Reference Project

Medical Device Reprocessing Unit

| Client | m-sas GmbH |

| Industry | Reprocessing of medical devices |

| Project type | New building/ Green Field |

| Role P³ | Project Management, Quality Management, Specialist Planning, Order Management, Construction Coordination |

| Area | approx 1,300 sqm (production area) |

| Duration | 06/2023 – 07/2024 |

| Trades | cleanroom systems, water treatment, ventilation technology, building services |

| Special features | Process equipment already selected, Shell construction status,very short response time |

| Objective | Solution |

| Ensuring cleanroom status |

Use of high-performance solutions HVAC system, state-of-the-art wall system |

|

Optimal room conditioning for operation |

Cooling circuit including a deep well |

| Sustainable and secure energy supply |

PV storage, emergency power generator |

Pharmaceutical gas supply of a university hospital

|

Client |

University Hospital |

|

Industry |

GMP Cleanroom/ Hospital |

|

Project type |

Building in existing buildings |

|

Scope |

Gas distribution networks for N2, LIN, CO2, pharm. CA |

|

Role P3 |

Quality Management |

|

Trade |

Technical building equipment |

|

Status |

ongoing |

|

Achievements |

LIN supply network successfully qualified |

Production of Unit Dose for Closed Loop Medication Management in a University Hospital

|

|

|

|

Client |

University Hospital |

|

Industry |

GMP Cleanroom/ Hospital Pharmacy |

|

Project type |

Building in existing buildings |

|

Size |

86 sqm |

|

Scope |

Manufacture of Unit Dose, ISO 8 |

|

Role P3 |

Concept study, client representation, cleanroom planning/ ventilation / process technology, qualification |

|

Trade |

Functional Performance Specification, Cleanroom Planning, Process Technology Planning |

|

Status |

2024, ongoing |

|

Achievements |

Invitation to tender as client representative (FLB for GÜ), preparation of a market analysis for unit dose machines, workshop on the process flow, developing layout of manufacturing areas |

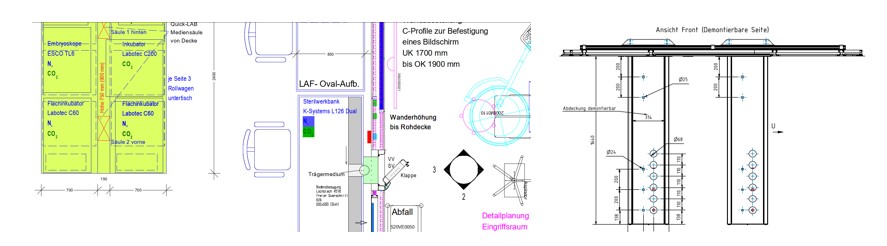

IVF laboratory including pharmaceutical gas supply of a university hospital

|

|

|

|

Client |

University Hospital |

|

Industry |

Hospital |

|

Project type |

Building in existing buildings |

|

Size |

97 sqm (Laboratory, storage, procedure room, airlock, preparation, technical room) |

|

Role P3 |

Project management, quality management, planning phases 2-8, order management, construction coordination/site supervision phase 8, Qualification (URS, RA, DQ, IQ, OQ) |

|

Trade |

Cleanroom systems, air handling technology, furniture, air technology |

|

Status |

2023/2024 |

|

Achievements |

Integration of a laboratory with GMP requirements into hospital environment, optimization of the functionality and work processes of the IVF laboratory |